服务承诺

资金托管

资金托管

原创保证

原创保证

实力保障

实力保障

24小时客服

24小时客服

使命必达

使命必达

51Due提供Essay,Paper,Report,Assignment等学科作业的代写与辅导,同时涵盖Personal Statement,转学申请等留学文书代写。

51Due将让你达成学业目标

51Due将让你达成学业目标 51Due将让你达成学业目标

51Due将让你达成学业目标 51Due将让你达成学业目标

51Due将让你达成学业目标 51Due将让你达成学业目标

51Due将让你达成学业目标私人订制你的未来职场 世界名企,高端行业岗位等 在新的起点上实现更高水平的发展

积累工作经验

积累工作经验 多元化文化交流

多元化文化交流 专业实操技能

专业实操技能 建立人际资源圈

建立人际资源圈如何通过偏光片提高液晶显示器的性能--加拿大Paper代写范文

2016-12-02 来源: 51Due教员组 类别: Paper范文

加拿大Paper代写范文:“如何通过偏光片提高液晶显示器的性能”,这篇论文主要描述的是偏光片是液晶显示器成像中必不可少的一部分,它有着高水平的折射层和同性层,能够合理的控制正交轴指数的折射率差,也就是说在液晶显示屏中使用偏光片能够提高显示屏的背光效率,也能够降低显示屏使用的功耗,进而提高液晶显示器的性能。

Abstract

A multilayer birefringent reflective polarizer film is described. This film has high refractive index difference between the birefringent and isotropic layers in the stretch direction and substantially matched indices in the remaining orthogonal axes.This film has high refractive index difference between the birefringent and isotropic layers in the stretch direction and substantially matched indices in the remaining orthogonal axes.

1. Introduction

The existence of birefringent multilayer reflective polarizers that reflect light of one polarization orientation and transmit light having the orthogonal polarization orientation is well known.Such reflective polarizers are commonly used in liquid crystal displays to recycle and re-transmit light not normally utilized by the display, thereby improving backlight efficiency and reducing power consumption of the display, and are sold by 3M Company as Vikuiti? Dual Brightness Enhancement Films (DBEF) In a simplified view, birefringent multilayer reflective polarizers are produced via coextrusion of alternating layers (1,2,1,2,1…) of two thermally processable polymers followed by uniaxial

stretching of the multilayer stack. The polymeric materials are chosen such that one material (1) is positively birefringent (refractive index increases with orientation) and the other material

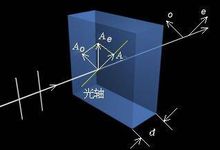

(2) is isotropic or minimally birefringent. In each pair of alternating layers 1 and 2 (referred to as the unit cell), the optical thickness of the two layers is substantially equal. To obtain reflectivity over a range of wavelengths, the multilayer film consists of a variety of unit cell thicknesses. The stretching process serves to increase the refractive index of the birefringent material in the stretch direction and decrease the refractive indices in the remaining two directions, whereas the isotropic material largely remains unchanged. Figure 1 shows a schematic representation of one unit cell of the multilayer film, wherein n1 refers to the refractive indices of the birefringent material and n2 refers to the isotropic material.

Ideally, one wishes to maximize the difference in refractive index in the stretch direction between the two layers, Δnx, since the reflectivity of each unit cell is strongly related to this index difference. Additionally, it is necessary that the index difference between the two layers of the unit cell in the y-direction (Δny) be zero or near zero in order to maximize the transmission of the desired polarization state. Lastly, it is also desired to substantially maintain an index match in the remaining orthogonal direction for both layers, Δnz. Failure to do so will result in undesirable reflectivity of p-polarized light in the z-y plane. This reflectivity can result in unwanted color artifacts in transmitted light and thus,in the liquid crystal display.

Figure 1. Schematic of the ideal reflective polarizer unit cell To produce ideal multilayer films of the type described above and represented in equations (1) and (2), the material must be stretched in a fashion such that y and z directions are deformed equally and the resultant refractive indices in these directions are equal. One method to achieve this ideal deformation is an unconstrained uniaxial stretch. In this case, the film is allowed to contract or relax in the y and z directions equally while being stretched in the x direction. A batch stretching technique is shownin Figure 2.

Figure 2. Batch Uniaxial Orientation

In this technique the film is gripped on opposite edges and drawn in the direction of the arrows. The resultant film piece contains a central portion that is stretched ideally and can be described by Stretch Direction

nx1

ny1and nz1

nx2

ny2 and nz2

z

x

y

nx1>>nx2 (1)

ny1=ny2=nz1=nz2=nx2 (2)

Good material

Wrinkles

YDDR = ZDDR = 1/ XDDR

1528 ? SID 06 DIGEST ISSN0006-0966X/06/3702-1528-$1.00+.00 ? 2006 SID

45.1 / M. E. Denker

equation (3). YDDR, XDDR and ZDDR refer to the x, y and zdirection draw ratios. This orientation method suffers from low yield and small part size and cannot be considered a viable method for large scale polarizer production. A conventional length orienter (LO) draws the film longitudinally in the machine direction across a span between rollers of differing speed. Because the film is not constrained in the span between rollers, the film can neck down in width as well as thin in caliper as it draws to afford films with nearly matched y and z indices.

Because of the large neck down in width, this process can be limited to smaller part size or require wide film dies to make parts of sufficient size for larger liquid crystal displays. Also, this method tends to amplify film imperfections such as die lines and create surface imperfections from the rollers. Among conventional continuous uniaxial stretching methods, the divergent rail tenter oven is the most attractive for making multilayer birefringent reflective polarizer in terms of yield, stretch uniformity, and surface appearance quality. In a divergent rail tenter, the input film is grasped at both edges by a plurality of clips connected to chains that ride on a set of rails. The film is preheated and then stretched in the x, or transverse direction as the rails diverge from one another (see Figure 3).

Figure 3. Conventional Tenter Oven

Since the speed of the clips is maintained during the stretch process, the film is constrained in the y-direction (machine direction) and is dimensionally unchanged in this direction after the stretching process. The z-direction is unconstrained during stretching, and thus, the film thins significantly during the stretch process as the film relaxes in the z-direction. The transverse direction draw ratio (TDDR) may be defined as width of a portion of the film after stretching divided by the initial width of that portion. The draw ratio in the machine direction and the zdirection

are:

MDDR = 1 (4)

ZDDR = 1/TDDR (5)

Thus, in a constrained uniaxial stretching process, the y-direction and z-direction draw ratios are not equal, and as a result, the refractive indices in the birefringent material in those directions, ny1 and nz1, are not equal. In this case, Δny and Δnz cannot both be zero since ny1 ≠ nz1 and ny2 = nz2 (isotropic). By proper selection of birefringent and isotropic polymeric materials, multilayer birefringent reflective polarizers can be made on conventional tenters where nx1 >> nx2 and ny1 = ny2. When the conventional tenter shown in Figure 3 is used, it is difficult to achieve Δnz that is equal to zero, and usually Δnz can only be minimized. Table 1 shows the an example of refractive indices of a reflective polarizer made on the conventional tentering apparatus shown in Figure 3 using traditional methods.

Table 1. Refractive Indices Via Conventional Tentering.

Typical Refractive Index

Axis

Birefringent Layer Isotropic Layer Δn

TD 1.78 1.62 0.16

MD 1.62 1.62 0.00

ZD 1.54 1.62 -0.08

Our objective in the current work is to create an ideal birefringent multilayer reflective polarizer, termed APF (Advanced Polarizer Film), with high reflective efficiency and excellent color uniformity of transmitted light, via a continuous orientation process whereby the indices in the resultant film layers are matched in the non-stretch direction (y and z) and the index difference between layers in the stretch direction is maximized.

结果 2. Results

We have developed a tentering apparatus that allows for contraction, or relaxation, of the film in the machine direction while it is stretched in the transverse direction. The film also thins while being stretched, as in a conventional tentering apparatus. The relationship between the draw ratios of the 3 principle axes is given in equation (3), above. While affording an ideal uniaxial stretch, this tentering apparatus maintains the advantages of conventional tenter oven, i.e. a large width yield increase and surface contact-free processing.3 Table 2 shows the refractive indices of the birefringent and isotropic layer of a polarizer made on this apparatus. Films made in this manner have a large index difference in the stretch directions and indices in the remaining directions that are substantially matched.

Table 2. Refractive Indices Via Ideal Tentering.

Typical Refractive Index

Axis

Birefringent Layer Isotropic Layer Δn

TD 1.84 1.57 0.27

MD 1.57 1.57 0.00

ZD 1.57 1.57 0.00

Figure 4 shows the transmission of light of APF made on this tenter. The plot traces show 1) the transmission of p-polarized light incident at 60° from normal for the desired pass state polarization, and 2) the transmission of light normal to the reflective polarizer for the blocked polarization state.

The 60° transmission data shows that APF has high transmission of non-normal incident light as a result of the z-index match. The light transmission is uniform and does not vary with wavelength.

Cast

Web Pre-Heat Stretch

Output

Stretched

Film

Tenter

Chain

V in

Vout=

OVEN

SID 06 DIGEST ? 1529

45.1 / M. E. Denker

Non-uniformity, if sufficiently severe, can lead to detectable nonuniform color in a display unless other steps are taken to mitigate this color.

0

10

20

30

40

50

60

70

80

90

100

350 400 450 500 550 600 650 700

Wavelength (nm)

Transmission (%)

APF 60° Pass

APF 0° Block

Figure 4. 60° Pass and 0° Block State Transmission of APF The block state transmission of APF is low, delivering high reflectivity of the unwanted polarization orientation. High reflectivity translates into greater recycling of light and improves polarizing efficiency. The block transmission is also very uniform, lacking any significant “leaks” of light (areas of relatively higher transmission over a narrow wavelength band) that would reduce the overall polarizing efficiency of the film. Color non-uniformity in reflective polarizer films can be exacerbated by normal thickness variations within the film, in both the machine and transverse directions. The inherent color uniformity in ideal reflective polarizers affords robust color control, in spite of thickness variations. Figure 5 shows Dx and Dy color shift data for 60° p-polarized light for APF across a multitude of crossweb and downweb positions and samples. Dx and Dy refer to the color shift in a display with and without the reflective polarizer. As can be seen, APF has low color shift and the color shift is very uniformly distributed. Low color shift and good uniformity in the reflective polarizer improves the overall uniformity in the LC display, and may be particularly advantageous for larger display applications, such as LCD TVs and monitors.

As was stated earlier, the reflectivity (optical power) of the film is strongly dependent upon the index difference between layers in the stretch direction and APF has a >50% larger index difference than some reflective polarizers made on a conventional tenter. The improved polarizing efficiency allows for a reduction of the number of layers in the multilayer film, without a sacrifice in optical properties. Indeed, the APF film in current examples has only 33% of the layers of some conventional reflective polarizers, yet has greater polarizing efficiency. A measurement of its contrast ratio (pass transmission divided by block transmission) shows that APF is 80:1. Additionally, a reduction in the number of layers has a positive effect on the ability to control the uniformity of the reflectivity across the bandwidth.

Data

dy dx

APF APF

0.010

0.005

0.000

-0.005

-0.010

Boxplot of 60° p-polarization, dy, dx

Figure 5. Transmission of p-polarized Light at 60° Lastly, the reduction of total layer count affords a large reduction in overall thickness of the polarizing film. Table 3 compares the overall thickness of a Vikuiti? DBEF and a Vikuiti? BEF product with their APF analogues. DBEF is a thin reflective polarizer designed to be laminated to the bottom glass of the LCD module and BEF-RPIIr is a product that combines 3M’s light angle management film (BEF) with reflective polarizer. In both cases the APF analogues can be made more than 50% thinner. The thinness of the APF construction may be advantageous in applications where minimization of the display thickness is desired or needed. Examples of such uses are cell phones, PDA’s, notebook computers and automotive display applications.

Table 3. Thickness Comparison

Film

Film Thickness

(μm)

APF Analogue

Thickness

(μm)

DBEF 93 40

BEF-RPIIr 108 52

结论 3. Conclusions

A film orientation method affords a multilayer birefringent reflective polarizer that has high index difference between the birefringent and isotropic layers in the stretch direction, but substantially matched indices in the remaining orthogonal axes. The resulting polarizing films have high polarizing efficiency, excellent color uniformity and exceptional thinness and may find utility in all LC display applications.

51due留学教育原创版权郑重声明:原创留学生作业代写范文源自编辑创作,未经官方许可,网站谢绝转载。对于侵权行为,未经同意的情况下,51Due有权追究法律责任。

51due为留学生提供最好的服务,亲们可以进入主页了解和获取更多paper代写范文 提供美国作业代写以及加拿大math辅导服务,详情可以咨询我们的客服QQ:800020041哟。-xz